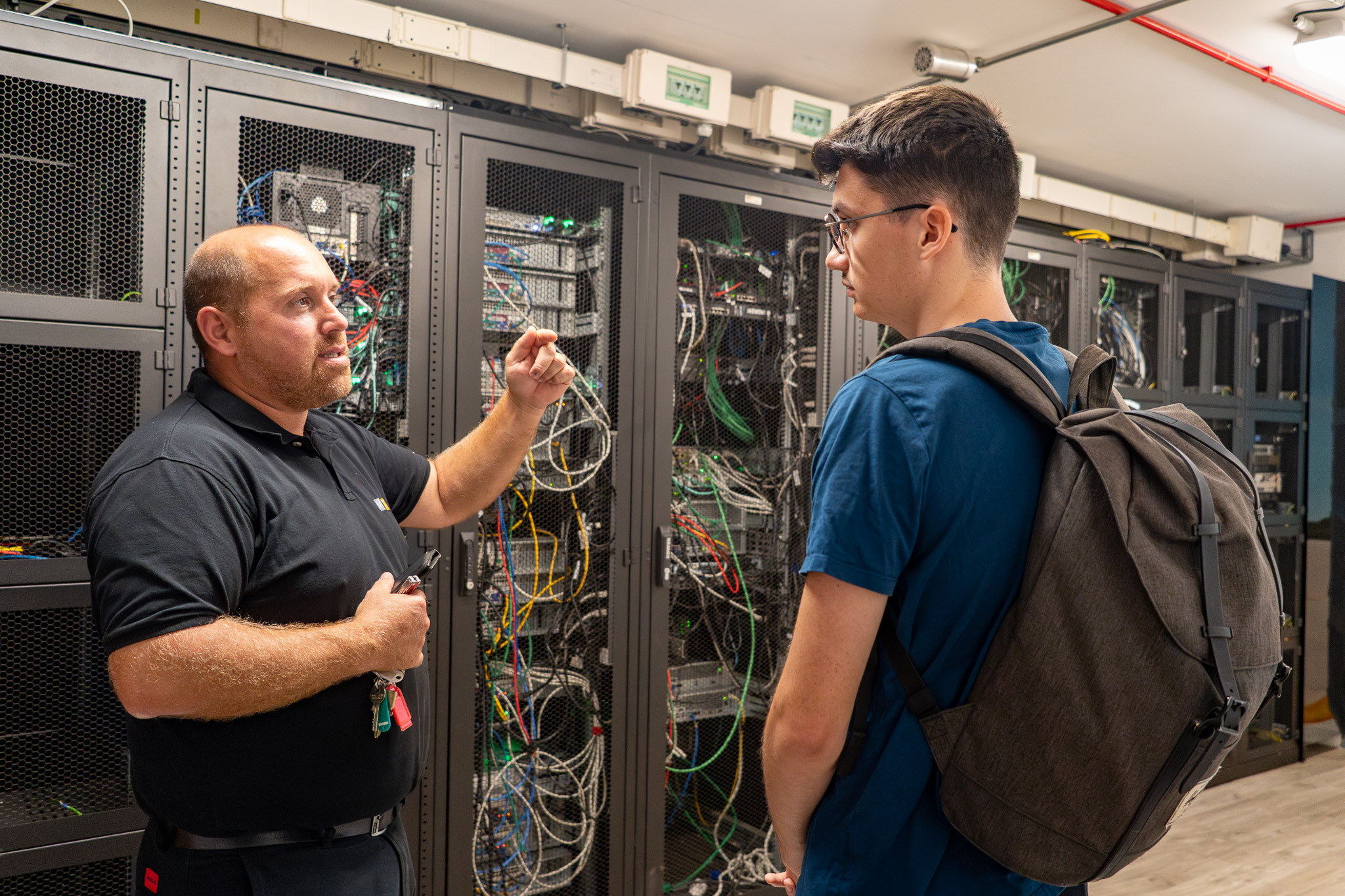

Oil cooling (or oil cooling in English) in the field of data centers is a method of cooling a server’s electronic components by using dielectric oil instead of air or water. This technique aims to dissipate the heat generated by electronic components more efficiently than conventional cooling methods.

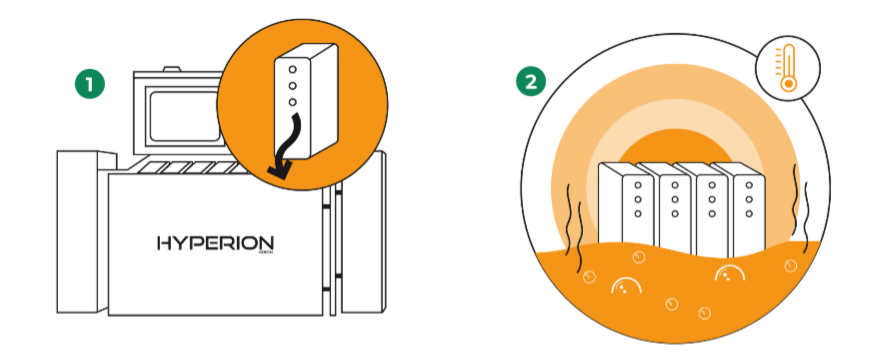

Here’s how oil cooling works for data centers (via our HYPERION solution):

1 – Immersion: The electronic components, such as the motherboard, processor, graphics card, etc., are directly immersed in a specially designed dielectric oil tank, like our HYPERION tank.

2 – An excellent heat conductor, the oil efficiently transfers heat from the components to the surrounding oil.

3 – Heat dissipation: Once submerged, the electronic components generate heat during operation. This heat is absorbed by the oil, helping to maintain a stable temperature for the components.

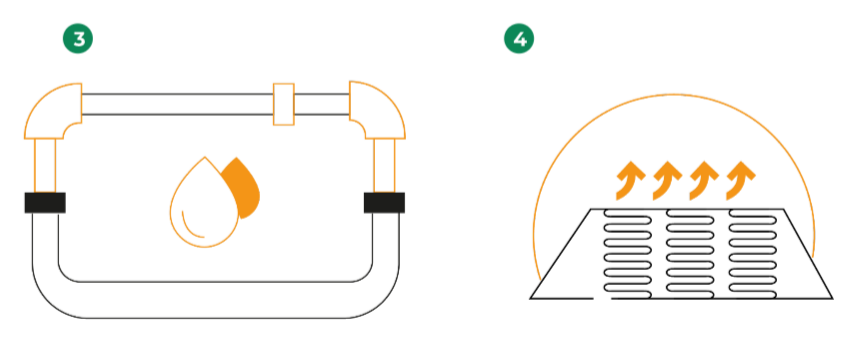

4 – The oil is then cooled using radiators or heat exchangers located outside the tank. In the case of our HYPERION solution, the oil is cooled using a plate heat exchanger system.

Oil cooling: What are the benefits for a business?

Oil cooling offers several advantages in terms of safety, performance, and ecology. Indeed, oil cooling provides better heat dissipation and the ability to cool high-performance and overclocked components more efficiently. Moreover, this system reduces noise as there is no need for air conditioning. With our HYPERION system, maintenance is relatively simple, and we invite you to learn more right here.

Heat dissipation and energy and environmental challenges are a concern for all businesses. In this context, oil cooling is a solution to prioritize, especially for high-performance data centers or research laboratories, where effective heat dissipation is essential.

Oil cooling: a solution for the future

Oil cooling, also known as immersion cooling, is considered a promising solution for several reasons:

- Its thermal efficiency: One of the main reasons why oil cooling is promising is its thermal efficiency. Oil has a much higher heat transfer capacity compared to air, meaning it can absorb and dissipate heat more effectively. This helps maintain lower temperatures for electronic components, which can extend their lifespan and improve their stability. Additionally, our HYPERION oil cooling solution operates without the need for air conditioning.

- Passive cooling: Oil cooling is typically passive, meaning it does not use noisy fans or pumps. This feature helps reduce noise in computing environments, which can be important in data centers and other facilities.

- Uniform cooling: Oil cools all components evenly since they are all submerged in the same medium. This eliminates potential hotspots and ensures an even heat distribution, which is crucial for intensive computing workloads.

- Space-saving: Oil cooling systems can be more compact than conventional air cooling solutions, as they don’t require large air conditioners or complex ducting. This can help save space in data centers and IT facilities.

- Cooling of high-performance components: As increasingly powerful computer components generate more heat, oil cooling provides an effective solution to cool these high-end components, which is crucial for intensive computing applications, artificial intelligence, digital modeling, and more. It doesn’t require fans, meaning no dust or oxidation, which gives it the added advantage of increased longevity.

- Energy savings: Although the heat exchangers required to cool the oil consume energy, the increased efficiency of oil cooling can ultimately lead to net energy savings compared to traditional cooling systems. The biggest saving comes from the fact that oil cooling via our HYPERION solution requires no use of air conditioning.