To develop our immersive data center solution, our company called on a renowned laboratory based in Dinan: Le laboratoire du Pôle Cristal. Equipped with 4 climatic cells, temperature-controlled hydraulic loops and extensive instrumentation capacity (temperature, pressure, hygrometry, air speed, electrical values), our HYPERION solution has been tested in optimal configurations. A look back at the various tests and technical trials carried out in 2022

Heat recovery performance for Hyperion: conclusive tests

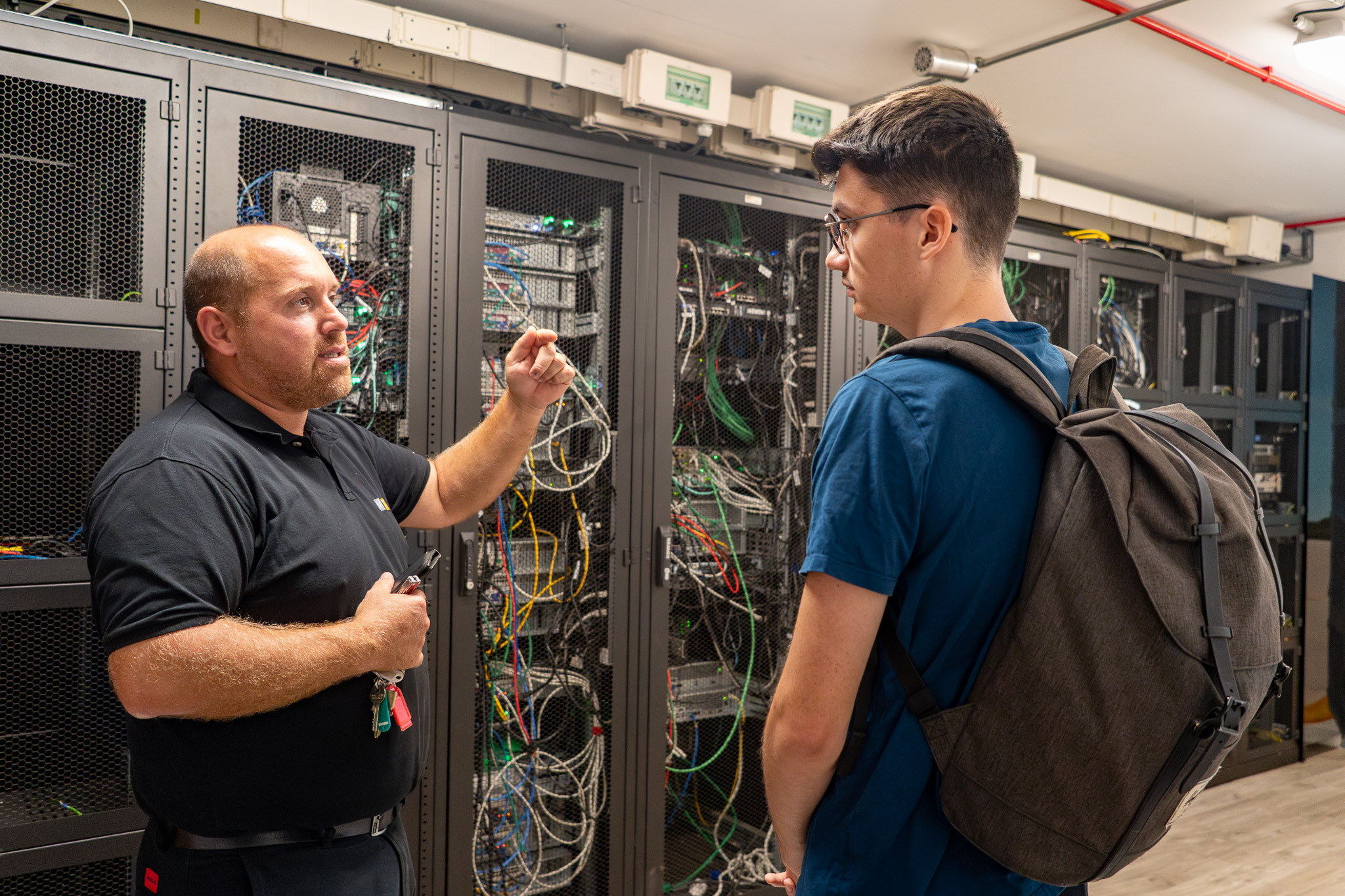

Feedback on the tests

After a whole expedition, HYPERION arrives at the Pôle Cristal in Dinan. It is a whole series of examinations that our tank is getting ready to undergo, as it is being fitted with 10 thermocouples throughout its interior… The aim is to monitor temperatures, detect the presence of hot spots and check the homogeneity of the temperature.

The testing process consisted of 6 steps:

Step 1: filling the tank

Step 2: Flow test 1: 2.5 m3/h

Stage 3: Flow test 2: 1m3/h

Step 4: Water + oil cut-off test,

Step 5: emptying, draining, cleaning

Step 6: Analysis of the results.

The implementation of these various stages enabled us to evaluate :

- power control,

- warm-up identical to servers,

- equivalent fluid dynamics,

- the glycoled water cooling loop (Ethylene Glycol 25%).

In total, 3 different types of oil were tested on our Hyperion solution, with conclusive results.

Thank you all for the smooth running of these tests!